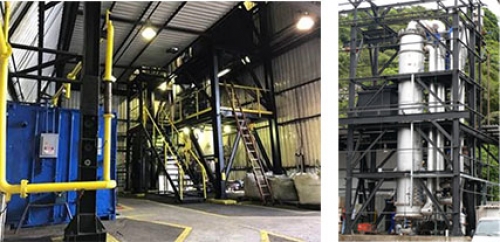

Carbogas was founded in 1976, working on its own thermochemical projects. Initially, the company's core business consisted in making industrial plants for the conversion of mineral coal into fuel gas. Due to the political and economic situation at the period, linked to a high cost of gas supply, it was worth for companies to produce their own fuel from coal. In this model, the first unit of Carbogas was sold in 1978, with certification and approval from Promon Engenharia Company. The success of the first project led to the sale of over twenty units, installed in South America and China. In 2000, Carbogas Energia made its own laboratory plant in São Paulo state, with an installed capacity of 1MWth, being the largest thermochemical laboratory in the world. In this plant, several researches and technological developments were conducted. In 2007, a partnership was signed with Vale, one of the biggest mining company in the word, for studies on gasification in fluidized beds reactors using industrial waste as fuel. After the success of the project, the partnership ended in 2011 with the creation of the technological patent, which is shared by the two companies (50/50). Afterwards, Carbogas Energia started to conduct its own research and development. From 2012 to 2016, several improvements were made to the unit to convert industrial and municipal solid waste into synthesis gas and, in parallel, the process for processing waste into homogenous solid fuel was developed and optimized, generating an automated line for RDF – Residue Derivated Fuel. This RDF was used as fuel in all tests carried out by Carbogas Energia. Finally, after all the technological development has matured, a work was carried out to monitor and analyze atmospheric emissions with the participation of the Environmental Company of the State of São Paulo (CETESB), a team from the University of São Paulo (USP) and the company Société Générale de Surveillance (SGS SA), a Swiss company recognized worldwide for environmental control work and certification. This team made a test plan with measurements of gases in the chimney, without filters, from the oxidation of synthesis gas generated at the thermochemical treatment of urban waste, to control all atmospheric emissions. The results showed that the process is clean and sustainable, as it is in line with all current environmental resolutions. Thus, Carbogas Energia nowadays develops sustainable solutions for the final destination of urban and industrial solid waste, in order to add economic and environmental sustainability to this field, by providing a clean fuel from the waste, in line with national and international environmental regulations and resolutions, such as the UN 2030 agenda.